What Is a PLC ? Basics for Beginners

In the bustling world of industrial automation, there’s a silent hero working tirelessly behind the scenes — the Programmable Logic Controller, or PLC. Imagine a world where complex processes run seamlessly, where machines communicate like an orchestra in perfect harmony. That’s the world PLCs help orchestrate. For those new to this domain, let’s embark on a journey to unravel the mysteries of these digital maestros and their critical role in modern control systems. As we explore, we’ll bridge the gap between everyday logic and the intricate dance of automation, making the inaccessible world of PLCs a tad more tangible.

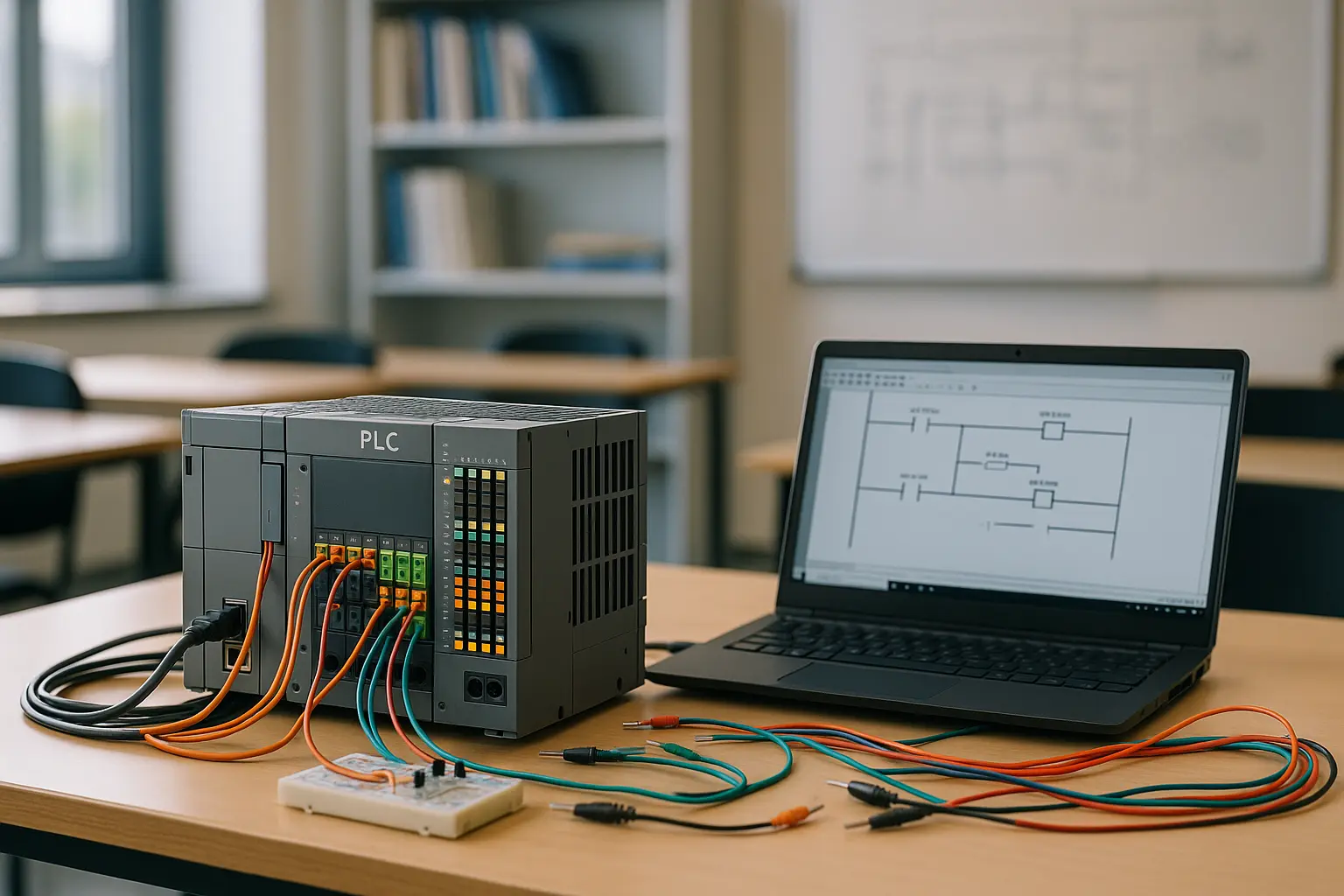

Understanding the Basics of PLCs

At its core, a PLC is a specialized computer designed to automate industrial processes. It begins as a simple concept but unfolds into a complex world of logic, programming, and control systems.

Consider the traditional relay logic, where mechanical switches were used to control operations. Early innovations in logic involved cumbersome arrays of wiring and switches. This setup, while revolutionary for its time, was inefficient and prone to failure. Enter the PLC, designed to revolutionize this mechanism by digitizing the control process.

PLCs work by taking various inputs, such as sensors or data signals, and processing them through a pre-written program. This program is akin to a well-composed orchestral score, where each note and rest determines the system’s operation. As the inputs are analyzed, outputs are generated, directing actions like switching valves, moving conveyor belts, or launching assembly lines.

The beauty of a PLC lies in its flexibility. Unlike traditional systems based on relays, which demanded extensive rewiring for changes, PLCs require only a software update. This ability to program and reprogram makes them indispensable in automation. They are the unsung heroes that ensure factories run smoothly, day in and day out.

The Language of Automation: Programming PLCs

To effectively utilize a PLC, one must speak its language — the language of programming. This realm, however, isn’t as daunting as it might seem.

PLC programming introduces us to several languages, each suited to different needs. The most commonly used is the ladder logic. Picture an electrical diagram; now replace the wires with logical connections, and you’ve essentially got ladder logic. With its intuitive design, it mirrors the old relay systems, making it accessible even to those new to programming.

Beyond ladder logic, there are other languages like Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Charts (SFC). Each has its unique attributes and strengths, allowing programmers to craft solutions tailored to specific challenges.

When we program a PLC, we’re essentially writing a set of rules for how inputs are transformed into outputs. Imagine telling a story where every action has a corresponding reaction. Our logic dictates how these elements interact, ensuring that every component of the system performs its intended function.

Modern PLCs provide robust platforms for automation. With the right programming, they can handle complex tasks, from simple machinery controls to advanced data systems. The digital age has transformed PLCs into versatile and dynamic controllers that continue to adapt to the ever-evolving industrial landscape.

The Architecture of a PLC System

Peering inside a PLC system reveals a marvel of engineering and design. The architecture of a PLC is a seamless integration of controllers, modules, and interfaces, all working in concert to execute intricate processes.

The foundation of a PLC is its central processing unit (CPU), the brain behind the operations. It’s here that the magic happens, where inputs are processed, and outputs are determined. Flanking the CPU are various input/output (I/O) modules, each responsible for interfacing with the external world. These modules collect data from sensors and send signals to actuators, bridging the gap between digital instructions and physical actions.

A vital component of the PLC architecture is its communication module, which permits interaction between different systems and devices. This ensures that all parts of an automated system work in harmony, sharing data and responding to changes in real-time.

Modern PLC systems often include diagnostic tools and interfaces, offering insights into operations and potential issues. These features enhance reliability, ensuring the system remains robust even under demanding conditions.

As we delve deeper into the architecture, it’s evident that PLCs are much more than mere controllers. They are sophisticated hubs of automation, directing an orchestra of machines, ensuring precision, efficiency, and reliability in every industrial scenario.

The Evolution and Future of PLCs

From humble beginnings, PLCs have evolved into pivotal components of modern industry. As digital technology progresses, so does the function and capability of these ingenious devices.

In the early days, PLCs were bulky, limited in function, and primarily used for simple tasks. However, advancements in technology have transformed them into compact, powerful devices capable of complex operations. Today’s PLCs boast faster processing speeds, increased memory, and enhanced communication capabilities, integrating seamlessly into data systems.

The future of PLCs is intertwined with the rise of the Industrial Internet of Things (IIoT) and smart manufacturing. As industries seek greater efficiency and connectivity, PLCs will play a crucial role in creating intelligent automation systems. These systems will not only control processes but also analyze and adapt to changing conditions in real-time.

Moreover, the development of artificial intelligence (AI) and machine learning technologies promises to further elevate the capabilities of PLCs. As these technologies converge, we can anticipate a new era where PLCs are not just reactive controllers but proactive partners in the quest for industrial excellence.

In this exciting future, PLCs will remain at the heart of innovation, guiding industries toward a more connected, intelligent, and automated world.

As we reflect on our deep dive into the world of PLCs, it’s clear that these devices are more than mere components of automation. They’re the pulse of progress, driving industries forward with unwavering precision and adaptability.

We’ve explored the foundational logic that underpins their operation, delved into the programming languages that bring them to life, and uncovered the intricate systems that define their architecture. Each step of our journey has revealed the evolving nature of PLCs, showcasing their ability to adapt and thrive in an ever-changing industrial landscape.

Looking ahead, PLCs will continue to be at the forefront of innovation, leading the charge toward smarter, more automated processes. As we embrace this future, let us celebrate the ingenuity and brilliance of PLCs, the unsung heroes of modern industry.

In our ever-connected world, the Programmable Logic Controller is not just a tool — it’s a testament to human creativity and our relentless pursuit of progress. PLCs are indeed the digital heart of modern industries, guiding us into a new era of seamless efficiency and boundless potential.

FAQ

What does PLC stand for and what is its primary function?

PLC stands for Programmable Logic Controller. It is an industrial digital computer designed to control manufacturing processes, such as assembly lines or robotic devices, ensuring operations are executed efficiently and precisely.

How does a PLC differ from a regular computer?

Unlike regular computers that are designed for general-purpose computing tasks, PLCs are specifically built to handle harsh industrial environments and are optimized for real-time processing, reliability, and durability.

What are the main components of a PLC system?

A typical PLC system consists of a CPU (central processing unit), input/output modules, power supply, and a programming device. The CPU processes data and executes control instructions, while I/O modules interface with external devices to gather input data and send out commands.

Can you explain how PLCs are programmed?

PLCs are programmed using specialized software and languages, with Ladder Logic being the most common. This language uses symbols that represent electrical relay logic to create the control sequences required for industrial processes.

What are the advantages of using PLCs in industrial automation?

PLCs offer several benefits including high reliability, ease of programming and reprogramming, scalability, and flexibility. They can easily adapt to changes in the production process and are designed to withstand industrial conditions such as extreme temperatures and vibrations.