What Is a Smart Factory? Explained Simply

In today’s rapidly evolving industrial landscape, the concept of the smart factory has emerged as a beacon of modernization and innovation. As we stand on the threshold of a new era in manufacturing, understanding the nuances of this transformation is crucial not only for industry insiders but also for those intrigued by the future of production. Our journey into the world of smart factories is not just about machines and technology; it’s about a symphony of data and processes harmonizing to redefine efficiency and productivity. Let’s explore how digital operations are revolutionizing the factory floor and shaping the future of industrial systems.

The Evolution of Manufacturing: From Past to Present

It’s a tale as old as time, the evolution of manufacturing. From artisan craftsmanship to mechanized assembly lines of the Industrial Revolution, each phase has brought about monumental changes. Today, we find ourselves at the cusp of yet another transformation. Enter the smart factory, where digital meets physical, and innovation is at its core.

Why now? As we delve into the reasons behind this shift, we must consider the vast amounts of data generated daily. These data points are invaluable, offering insights that were once unimaginable. They guide us, informing decisions and streamlining processes like never before.

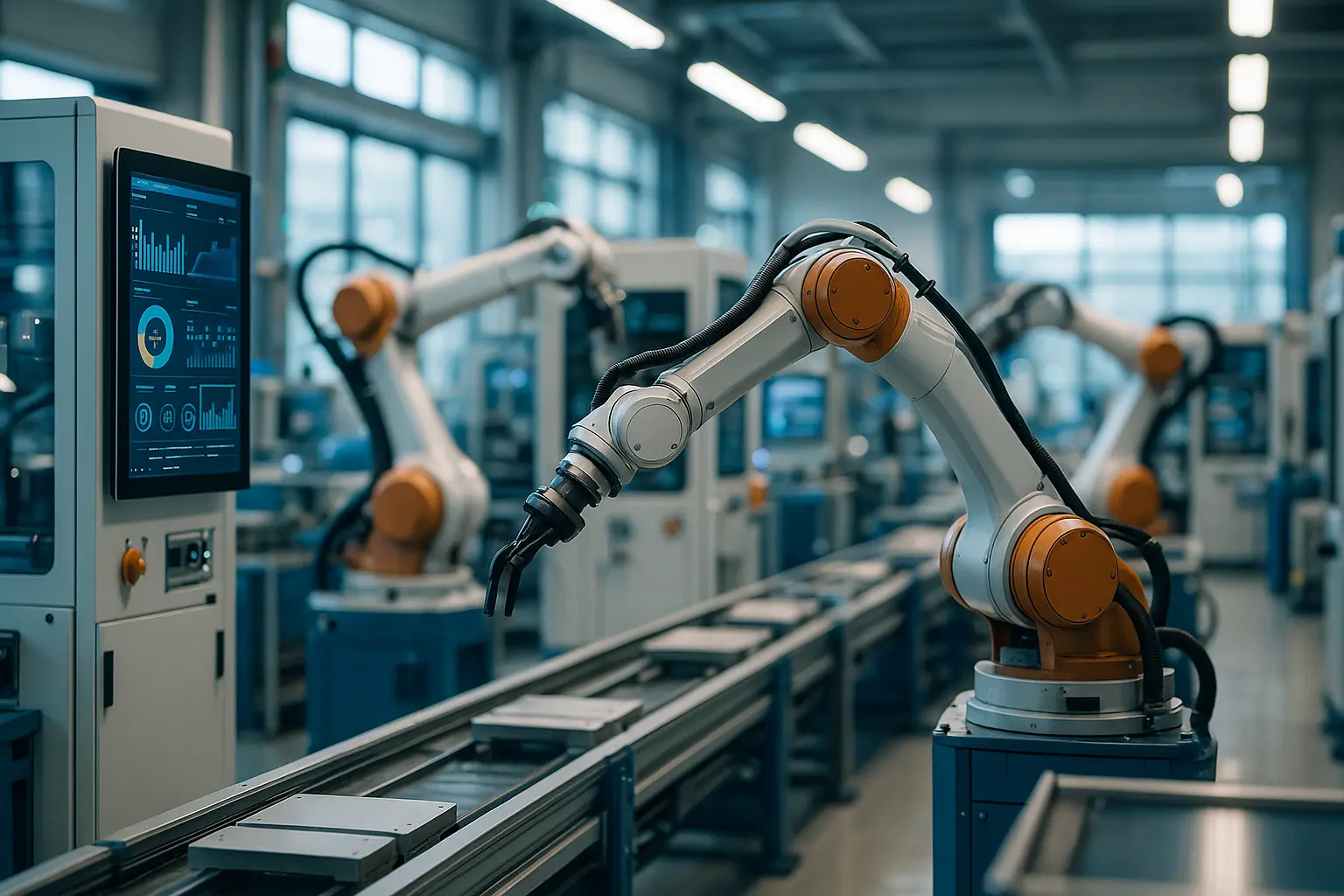

While machinery continues to advance, it’s the integration of technology that truly sets a smart factory apart. By embracing systems that can self-optimize and adapt, we unlock potential levels of production efficiency previously unattainable in traditional factories. Machines can now communicate with each other, adjusting better and faster, ensuring that every part of the production process is in sync.

But what exactly defines a smart factory? It’s not merely about automation; it’s about digital transformation. We see processes that adapt in real-time, utilizing advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning. These aren’t just buzzwords, but vital components that drive this modern factory narrative.

In the past, innovation in factories happened in waves. Today, it flows constantly, like a river, altering every aspect of the manufacturing landscape. The evolution from traditional to smart factories isn’t merely a technological upgrade—it’s a paradigm shift, redefining how we perceive industrial operations and efficiencies.

Core Technologies Driving Smart Factories

When we speak of smart factories, the technology at play is nothing short of extraordinary. Imagine a concert where each instrument plays in perfect harmony—this is the level of efficiency achieved in a smart factory as each system and machine works in unison.

IoT: The Nervous System An integral part, the Internet of Things, acts as the nervous system, connecting various components of the factory. These connections allow for seamless communication and data sharing between systems, creating a dynamic and efficient production environment.

AI and Machine Learning: The Brain The implementation of AI and machine learning provides intelligence. These technologies allow facilities to predict maintenance needs, optimize processes, and even foresee potential disruptions. As a result, smart factories are proactive rather than reactive.

Digital Twins: The Reflection With digital twin technology, we create virtual replicas of physical assets. This technology provides invaluable insights, enabling us to model, test, and simulate scenarios without risk. It’s akin to having a crystal ball, providing foresight into potential process outcomes.

Advanced Analytics: The Insight Analytics connects the dots, offering clarity from complex data sets. It allows for precise decision-making and process enhancements, ensuring superior production outcomes. With analytics, we gain a 360-degree view of operations, transforming data into actionable insights.

In essence, smart factories are less about singular technologies and more about the synergy between them. They are environments where the digital and physical worlds intertwine, creating a tapestry of innovation that reshapes the very fabric of manufacturing as we know it.

Challenges and Solutions in Implementing Smart Factories

While the allure of smart factories is undeniable, the path to achieving such a transformation is fraught with challenges. As we navigate this journey, recognizing potential hurdles and their solutions is vital to our success.

Data Overload With the integration of smart technologies, factories generate immense amounts of data daily. The challenge lies in managing this data efficiently. Implementing robust data storage and processing systems is essential to harness the true potential of this information.

Cybersecurity Concerns Connectivity is a double-edged sword. While it enhances productivity, it also opens up vulnerabilities. Protecting sensitive industrial data requires state-of-the-art security protocols. Regular audits and a vigilant approach to cybersecurity ensure the integrity of operations.

Integration Complexities Bringing together legacy systems with modern technology can be daunting. It’s crucial to adopt a phased approach, ensuring compatibility and minimal disruption. Collaborative efforts with technology providers can also ease this transition.

Skill Gaps A workforce adept in handling advanced technologies is pivotal. Investing in training programs and upskilling current employees bridges this gap, ensuring a seamless transition to smart factory operations.

In confronting these challenges, smart factories are not just about technological prowess but about cultivating a mindset of resilience and adaptability. As we evolve, so must our strategies, ensuring that our journey towards smarter manufacturing is not just a goal, but a strategic evolution.

As we stand on the brink of this new era, the smart factory represents more than just a technological advancement; it symbolizes a fundamental shift in how we perceive manufacturing. With the seamless integration of data, machines, and human ingenuity, it carves a path toward unprecedented levels of efficiency and innovation.

The journey to smart factories is not merely a destination but an ongoing evolution. It challenges our conventions, urging us to rethink and reimagine the very essence of production. By embracing these changes, we unlock potential far beyond traditional constraints, crafting a future where the boundaries of what’s possible continuously expand.

In embracing this transformation, we, the architects of the future, hold the blueprint to not just smarter factories, but a smarter world. The future beckons, and it is our vision and perseverance that will shape the industrial landscapes of tomorrow.

FAQ

What defines a smart factory?

A smart factory is an advanced manufacturing facility that utilizes cutting-edge technology to automate and optimize production processes. These factories integrate Internet of Things (IoT) devices, artificial intelligence (AI), robotics, and data analytics to enhance efficiency and adaptability.

How does a smart factory differ from a traditional one?

Unlike traditional factories, smart factories employ interconnected systems and real-time data to streamline operations. This integration allows for improved decision-making, predictive maintenance, and reduced downtime, making them more agile and responsive to market changes.

What are the core technologies used in smart factories?

Key technologies include IoT sensors for data collection, AI algorithms for data analysis, robotics for automation, and cloud computing for data storage and processing. These technologies work together to create a seamless, efficient production environment.

What benefits do smart factories offer to manufacturers?

Smart factories offer numerous benefits, including increased production efficiency, reduced costs, enhanced product quality, and the ability to quickly adapt to consumer demands. They also enable better resource management and environmental sustainability.

Are there any challenges associated with implementing a smart factory?

While the advantages are significant, implementing a smart factory can be challenging. It requires substantial investment in technology, skilled personnel to manage complex systems, and cybersecurity measures to protect sensitive data. Additionally, the transition may involve overcoming resistance to change within the workforce.